Page 14 - Heat_Exchanger_2020

P. 14

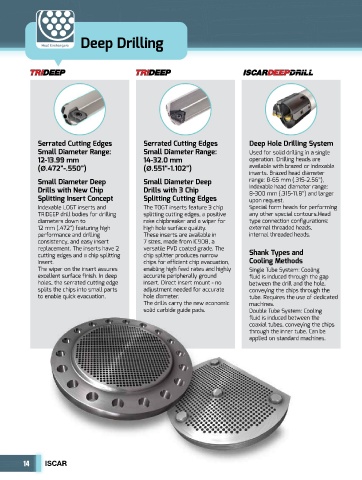

Deep Drilling

Heat Exchangers

Serrated Cutting Edges Serrated Cutting Edges Deep Hole Drilling System

Small Diameter Range: Small Diameter Range: Used for solid drilling in a single

12-13.99 mm 14-32.0 mm operation. Drilling heads are

(Ø.472”-.550”) (Ø.551”-1.102”) available with brazed or indexable

inserts. Brazed head diameter

Small Diameter Deep Small Diameter Deep range: 8-65 mm (.315-2.56”),

Drills with New Chip Drills with 3 Chip Indexable head diameter range:

8-300 mm (.315-11.8”) and larger

Splitting Insert Concept Splitting Cutting Edges upon request.

Indexable LOGT inserts and The TOGT inserts feature 3 chip Special form heads for performing

TRIDEEP drill bodies for drilling splitting cutting edges, a positive any other special contours.Head

diameters down to rake chipbreaker and a wiper for type connection configurations:

12 mm (.472”) featuring high high hole surface quality. external threaded heads,

performance and drilling These inserts are available in internal threaded heads.

consistency, and easy insert 7 sizes, made from IC908, a

replacement. The inserts have 2 versatile PVD coated grade. The

cutting edges and a chip splitting chip splitter produces narrow Shank Types and

insert. chips for efficient chip evacuation, Cooling Methods

The wiper on the insert assures enabling high feed rates and highly Single Tube System: Cooling

excellent surface finish. In deep accurate peripherally ground fluid is induced through the gap

holes, the serrated cutting edge insert. Direct insert mount - no between the drill and the hole,

splits the chips into small parts adjustment needed for accurate conveying the chips through the

to enable quick evacuation. hole diameter. tube. Requires the use of dedicated

The drills carry the new economic machines.

solid carbide guide pads. Double Tube System: Cooling

fluid is induced between the

coaxial tubes, conveying the chips

through the inner tube. Can be

applied on standard machines.

14 ISCAR