Page 9 - Heat_Exchanger_2020

P. 9

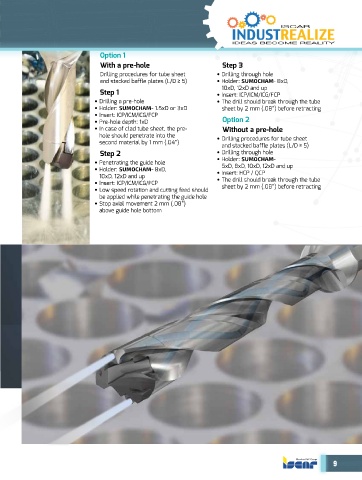

Option 1

With a pre-hole Step 3

Drilling procedures for tube sheet • Drilling through hole

and stacked baffle plates (L/D ≥ 5) • Holder: SUMOCHAM- 8xD,

10xD, 12xD and up

Step 1 • Insert: ICP/ICM/ICG/FCP

• Drilling a pre-hole • The drill should break through the tube

• Holder: SUMOCHAM- 1.5xD or 3xD sheet by 2 mm (.08”) before retracting

• Insert: ICP/ICM/ICG/FCP

• Pre-hole depth: 1xD Option 2

• In case of clad tube sheet, the pre- Without a pre-hole

hole should penetrate into the • Drilling procedures for tube sheet

second material by 1 mm (.04”)

and stacked baffle plates (L/D ≥ 5)

Step 2 • Drilling through hole

• Penetrating the guide hole • Holder: SUMOCHAM-

5xD, 8xD, 10xD, 12xD and up

• Holder: SUMOCHAM- 8xD, • Insert: HCP / QCP

10xD, 12xD and up

• Insert: ICP/ICM/ICG/FCP • The drill should break through the tube

sheet by 2 mm (.08”) before retracting

• Low speed rotation and cutting feed should

be applied while penetrating the guide hole

• Stop axial movement 2 mm (.08”)

above guide hole bottom

9