Page 20 - ISCAR Conseiller pour fraises_fr

P. 20

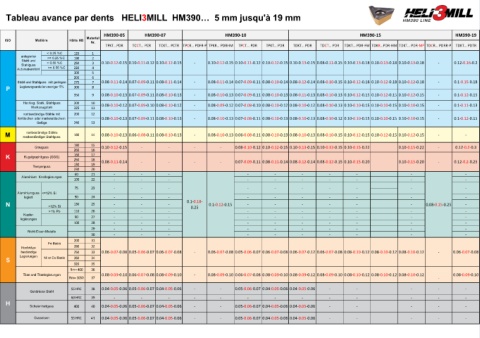

Tableau avance par dents HELI3MILL HM390… 5 mm jusqu'à 19 mm

HM390-05 HM390-07 HM390-10 HM390-15 HM390-19

Material

ISO Matière Härte HB

Nr.

TPKT...PDR TCCT… PCR TCKT… PCTR TPCR… PDFR-P TPKR… PDRHM TPCT… PDR TPKT… PDR TDKT… PDR TDCT… PDR TDKT… PDR-FW TDKR…PDR-HM TDKT… PDR-MP TDCR… PDRR-P TDKT… PDTR

< 0.25 %C 125 1

unlegierter >= 0.25 %C 190 2

Stahl und 0.10-0.12-0.15 0.10-0.11-0.12 0.10-0.12-0.15 - 0.10-0.12-0.15 0.10-0.11-0.12 0.10-0.12-0.15 0.10-0.13-0.15 0.08-0.11-0.15 0.10-0.13-0.18 0.10-0.13-0.18 0.10-0.13-0.18 - 0.12-0.16-0.2

Stahlguss < 0.55 %C 250 3

Automatenstahl >= 0.55 %C 220 4

300 5

200 6

Stahl und Stahlguss mit geringen 275 7 0.08-0.11-0.14 0.07-0.09-0.11 0.08-0.11-0.14 - 0.08-0.11-0.14 0.07-0.09-0.11 0.08-0.10-0.14 0.08-0.12-0.14 0.08-0.10-0.15 0.10-0.12-0.18 0.10-0.12-0.18 0.10-0.12-0.18 - 0.1-0.15-0.18

P Legierungsanteilen weniger 5% 300 8

350 9 0.08-0.10-0.13 0.07-0.09-0.11 0.08-0.10-0.13 - 0.08-0.10-0.13 0.07-0.09-0.11 0.08-0.10-0.13 0.08-0.11-0.13 0.08-0.10-0.13 0.10-0.12-0.15 0.10-0.12-0.15 0.10-0.12-0.15 - 0.1-0.12-0.15

Hochleg. Stahl, Stahlguss 200 10 0.08-0.10-0.12 0.07-0.09-0.10 0.08-0.10-0.12 - 0.08-0.09-0.12 0.07-0.08-0.10 0.08-0.10-0.12 0.08-0.10-0.12 0.08-0.10-0.13 0.10-0.10-0.15 0.10-0.10-0.15 0.10-0.10-0.15 - 0.1-0.11-0.13

Werkzeugstahl 325 11

rostbeständige Stähle mit 200 12

ferritischen oder martensitischem 0.08-0.10-0.13 0.07-0.09-0.11 0.08-0.10-0.13 - 0.08-0.10-0.13 0.07-0.08-0.11 0.08-0.10-0.13 0.08-0.10-0.13 0.08-0.10-0.12 0.10-0.10-0.15 0.10-0.10-0.15 0.10-0.10-0.15 - 0.1-0.12-0.15

Gefüge 240 13

M rostbeständiger Stahlguss 180 14 0.08-0.10-0.13 0.06-0.08-0.11 0.08-0.10-0.13 - 0.08-0.10-0.13 0.06-0.08-0.11 0.08-0.10-0.13 0.08-0.10-0.13 0.08-0.10-0.15 0.10-0.12-0.15 0.10-0.12-0.15 0.10-0.12-0.15 - -

rostbeständige Stähle

180 15

Grauguss 0.10-0.12-0.15 - - - - 0.08-0.10-0.12 0.10-0.12-0.15 0.10-0.13-0.15 0.10-0.13-0.15 0.10-0.15-0.22 0.10-0.15-0.22 - 0.12-0.2-0.3

260 16

K Kugelgraphitguss (GGG) 160 17

250 18 0.08-0.11-0.14 - - - - 0.07-0.09-0.11 0.08-0.11-0.14 0.08-0.12-0.14 0.08-0.12-0.15 0.10-0.15-0.20 0.10-0.15-0.20 - 0.12-0.2-0.25

130 19

Temperguss

230 20

60 21 - - - - - - - - - -

Aluminium Knetlegierungen

100 22 - - - - - - - - - -

75 23 - - - - - - - - - -

Aluminiumguss <=12% Si

legiert 90 24 - - - - - - - - - -

N >12% Si 130 25 - - - 0.1-0.18- 0.1-0.12-0.15 - - - - - - 0.08-0.15-0.25 -

0.25

>1% Pb 110 26 - - - - - - - - - -

Kupfer- 90 27 - - - - - - - - - -

legierungen

100 28 - - - - - - - - - -

29 - - - - - - - - - -

Nicht-Eisen-Metalle

30 - - - - - - - - - -

200 31

Fe Basis

Hochhitze 280 32

beständige 250 33 0.06-0.07-0.08 0.05-0.06-0.07 0.06-0.07-0.08 - 0.06-0.07-0.08 0.05-0.06-0.07 0.06-0.07-0.08 0.06-0.07-0.12 0.06-0.07-0.08 0.08-0.10-0.12 0.08-0.10-0.12 0.08-0.10-0.12 - 0.06-0.07-0.08

Legierungen Ni or Co Basis 350 34

S

320 35

Rm= 400 36

Titan und Titanlegierungen 0.08-0.09-0.10 0.06-0.07-0.08 0.08-0.09-0.10 - 0.08-0.09-0.10 0.06-0.07-0.08 0.08-0.09-0.10 0.08-0.09-0.12 0.08-0.09-0.10 0.08-0.10-0.12 0.08-0.10-0.12 0.08-0.10-0.12 0.08-0.09-0.10

Rm= 1050 37 -

55 HRC 38 0.04-0.05-0.06 0.05-0.06-0.07 0.04-0.05-0.06 - - 0.05-0.06-0.07 0.04-0.05-0.06 0.04-0.05-0.06 - - - - -

Gehärteter Stahl

60 HRC 39 - - - - - - - - - - - - -

H

Schalenhartguss 400 40 0.04-0.05-0.06 0.05-0.06-0.07 0.04-0.05-0.06 - - 0.05-0.06-0.07 0.04-0.05-0.06 0.04-0.05-0.06 - - - - -

Gusseisen 55 HRC 41 0.04-0.05-0.06 0.05-0.06-0.07 0.04-0.05-0.06 - - 0.05-0.06-0.07 0.04-0.05-0.06 0.04-0.05-0.06 - - - - -