Page 25 - MILLING CATALOG p001-094

P. 25

Shank Rd° ENDMILLS • SOLID CARBIDE • MULTI-MASTER

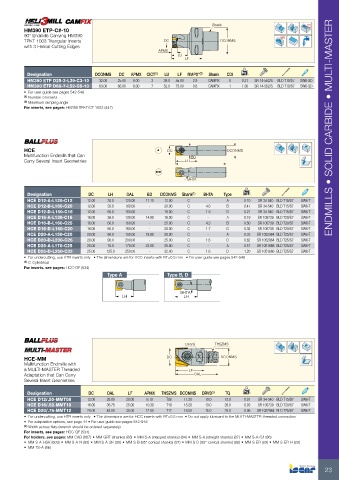

DCONMS

HM390 ETP-C#-10 DC

90° Endmills Carrying HM390 APMX

TPKT 1003 Triangular Inserts

with 3 Helical Cutting Edges

LU

LF

Designation DCONMS DC APMX CICT(1) LU LF RMPX°(2) Shank CDI kg

0

HM390 ETP D25-3-L39-C3-10 32.00 25.00 8.00 3 39.0 55.00 2.9 CAMFIX 1 0.21 SR 14-562/S BLD T10/S7 SW6-SD

HM390 ETP D66-7-L52-C6-10 63.00 66.00 8.00 7 52.0 75.00 0.8 CAMFIX 1.80 SR 14-562/S BLD T10/S7 SW6-SD

• For user guide see pages 542-548

(1) Number of inserts

(2) Maximum ramping angle

For inserts, see pages: HM390 TPKT/CT 1003 (447)

HCE A DC DCONMS

Multifunction Endmills that Can

Carry Several Insert Geometries B/D BD

LH

BHTA

Designation DC LH OAL BD DCONMS Shank(1) BHTA Type kg

HCE D12-A-L120-C12 12.00 30.0 120.00 11.10 12.00 C - A 0.10 SR 34-540 BLD T15/S7 SW6-T

SR 34-540 BLD T15/S7 SW6-T

HCE D12-B-L160-C20 12.00 50.0 160.00 - 20.00 C 4.6 B 0.41 SR 34-540 BLD T15/S7 SW6-T

SR 105739 BLD T20/S7 SW6-T

HCE D12-D-L160-C16 12.00 60.0 160.00 - 16.00 C 1.9 D 0.21 SR 105739 BLD T20/S7 SW6-T

SR 105739 BLD T20/S7 SW6-T

HCE D16-A-L130-C16 16.00 36.0 130.00 14.90 16.00 C - A 0.19 SR 1052964 BLD T25/S7 SW6-T

SR 1052964 BLD T25/S7 SW6-T

HCE D16-B-L160-C25 16.00 60.0 160.00 - 25.00 C 4.3 B 0.50 SR 1051666 BLD T25/S7 SW6-T

SR 1051666 BLD T25/S7 SW6-T

HCE D16-D-L160-C20 16.00 65.0 160.00 - 20.00 C 1.7 D 0.32

HCE D20-A-L150-C20 20.00 60.0 150.00 18.80 20.00 C - A 0.33

HCE D20-D-L200-C25 20.00 90.0 200.00 - 25.00 C 1.6 D 0.62

HCE D25-A-L170-C25 25.00 70.0 170.00 23.00 25.00 C - A 0.57

HCE D25-D-L250-C32 25.00 125.0 250.00 - 32.00 C 1.6 D 1.20

• For undercutting, use HTR inserts only • The dimensions are for HCC inserts with RE=0.5 mm • For user guide see pages 542-548

(1) C-Cylindrical

For inserts, see pages: HCC-QF (534)

Type A Type B, D

BHTA

LH LH

DRVS THSZMS

HCE-MM DC DCONMS

Multifunction Endmills with LF

a MULTI-MASTER Threaded OAL

Adaptation that Can Carry

Several Insert Geometries

Designation DC OAL LF APMX THSZMS DCONMS DRVS(1) TQ kg

HCE D12/.50-MMT08 12.00 28.00 20.00 8.10 T08 11.50 10.0 15.0 0.01 SR 34-540 BLD T15/S7 SW6-T

HCE D16/.62-MMT10

16.00 36.75 25.00 10.30 T10 15.20 13.0 28.0 0.03 SR 105739 BLD T20/S7 SW6-T

HCE D20/.75-MMT12

20.00 48.80 35.00 12.80 T12 18.50 15.0 28.0 0.06 SR 1052964 BLD T25/S7 SW6-T

• For undercutting, use HTR inserts only • The dimensions are for HCC inserts with RE=0.5 mm • Do not apply lubricant to the MULTI-MASTER threaded connection

• For adaptation options, see page 44 • For user guide see pages 542-548

(1) Width across flats (wrench should be ordered separately)

For inserts, see pages: HCC-QF (534)

For holders, see pages: MM CAB (667) • MM GRT (shanks) (86) • MM S-A (stepped shanks) (84) • MM S-A (straight shanks) (87) • MM S-A-C# (86)

• MM S-A-HSK (609) • MM S-A-N (85) • MM S-A-SK (90) • MM S-B (85° conical shanks) (87) • MM S-D (89° conical shanks) (88) • MM S-ER (89) • MM S-ER-H (89)

• MM TS-A (86)

23