Page 8 - parting_4_productivity_3375101

P. 8

W C

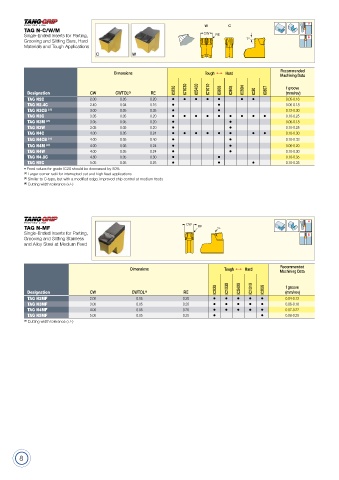

TAG N-C/W/M

Single-Ended Inserts for Parting, CW RE

Grooving and Slitting Bars, Hard 7º

Materials and Tough Applications

Recommended

Dimensions Tough 1 Hard

Machining Data

IC830 IC1030 IC5400 IC1010 IC808 IC908 IC30N IC807 f groove

Designation CW CWTOL (3) RE IC20 (mm/rev)

TAG N2C 2.00 0.05 0.20 • • • • • • • 0.05-0.16

TAG N2.4C 2.40 0.04 0.16 • • 0.06-0.18

TAG N3CB (1) 3.00 0.05 0.35 • • 0.12-0.30

TAG N3C 3.05 0.05 0.20 • • • • • • • • • 0.10-0.25

TAG N3M (2) 3.05 0.05 0.20 • • 0.06-0.18

TAG N3W 3.05 0.05 0.20 • • 0.10-0.25

TAG N4C 4.00 0.05 0.24 • • • • • • • • 0.10-0.30

TAG N4CB (1) 4.00 0.05 0.40 • • 0.10-0.33

TAG N4M (2) 4.00 0.05 0.24 • • 0.06-0.20

TAG N4W 4.00 0.05 0.24 • • 0.10-0.30

TAG N4.8C 4.80 0.05 0.30 • • 0.10-0.35

TAG N5C 5.05 0.05 0.25 • • • 0.10-0.35

• Feed values for grade IC20 should be decreased by 50%

(1) Larger corner radii for interrupted cut and high feed applications

(2) Similar to C-type, but with a modified edge; improved chip control at medium feeds

(3) Cutting width tolerance (+/-)

CW

TAG N-MF RE 7°

Single-Ended Inserts for Parting,

Grooving and Slitting Stainless

and Alloy Steel at Medium Feed

Recommended

Dimensions Tough 1 Hard Machining Data

IC830 IC1030 IC5400 IC1010 IC808 f groove

Designation CW CWTOL (1) RE (mm/rev)

TAG N2MF 2.00 0.05 0.20 • • • • • 0.04-0.12

TAG N3MF 3.00 0.05 0.20 • • • • • 0.06-0.18

TAG N4MF 4.00 0.05 0.25 • • • • • 0.07-0.22

TAG N5MF 5.00 0.05 0.25 • • 0.08-0.25

(1) Cutting width tolerance (+/-)

8