Page 12 - HOLE MAKING CATALOG p185-310

P. 12

DEEP DRILLING - BTA SYSTEM USER GUIDE

Spare Parts Insert Insert Clamping Screw Key N*m Solid Carbide Guide Pad Key

Guide Pad Clamping Screw

Diameter TOGT 070304-DT/GF T-7

Range TOGT 080305-DT/GF SR 14-560/S T-8 1.2 GPS-05-18-060-DC SR 34-508

TOGT 090305-DT/GF SR 14-560/S T-8 T-7/5

14.00-15.99 TOGT 100305-DT/GF SR 14-560/S T-8 1.2 GPS-06-20-075-DC SR 34-508 T-9/5

16.00-18.00 TOGT 100305-DT/GF SR11201753-4

18.01-20.00 TOGT 110405-DT/GF 1.2 GPS-06-20-085-DC

20.01-20.99 TOGT 120405-DT/GF

21.00-21.99 TOGT 130408-DT/GF SR 34-506 T-9 2.0 GPS-06-20-085-DC

22.00-25.00 TOGT 130408-DT/GF GPS-06-20-100-DC

25.01-28.00 TOGT 140510-DT/GF

28.01-29.99 TOGT 140510-DT/GF SR 14-571/S T-15 4.8 GPS-06-20-100-DC

30.00-32.00 SR 14-506 T-15

32.01-39.01 4.8 GPS-06-20-120-DC

39.01-40.00

GPS-06-20-120-DC

SR 16-212/L10 T20/5 10 GPS-07-20-120-DC

GPS-07-20-120-DC

GPS-08-25-155-DC

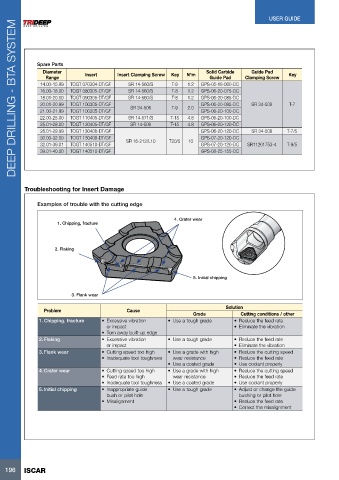

Troubleshooting for Insert Damage 4. Crater wear

Examples of trouble with the cutting edge

1. Chipping, fracture

2. Flaking

5. Initial chipping

3. Flank wear

Problem Cause Grade Solution

1. Chipping, fracture • Use a tough grade Cutting conditions / other

• Excessive vibration

2. Flaking or impact • Use a tough grade • Reduce the feed rate

3. Flank wear • Eliminate the vibration

• Torn away built-up edge • Use a grade with high

4. Crater wear • Excessive vibration wear resistance • Reduce the feed rate

• Eliminate the vibration

5. Initial chipping or impact • Use a coated grade • Reduce the cutting speed

• Cutting speed too high • Use a grade with high • Reduce the feed rate

• Inadequate tool toughness • Use coolant properly

wear resistance • Reduce the cutting speed

• Cutting speed too high • Use a coated grade • Reduce the feed rate

• Feed rate too high • Use a tough grade • Use coolant properly

• Inadequate tool toughness • Adjust or change the guide

• Inappropriate guide

bushing or pilot hole

bush or pilot hole • Reduce the feed rate

• Misalignment • Correct the misalignment

196 ISCAR