Page 18 - TURNING CATALOG p255-458

P. 18

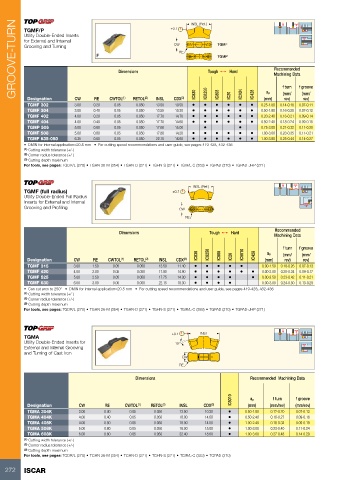

GROOVE-TURN TGMF/P INSL (Ref.)

Utility Double-Ended Inserts ±0.1

for External and Internal

Grooving and Turning CW TGMF

RE TGMP

Dimensions Tough 1 Hard Recommended

Machining Data

IC830 ap f turn f groove

IC8250

Designation CW RE CWTOL(1) RETOL(2) INSL CDX(3) IC808 (mm) (mm/ (mm/

IC20 rev) rev)

TGMF 302 IC20N 0.14-0.18 0.07-0.11

TGMF 304 IC428 0.16-0.20 0.07-0.12

TGMF 402 0.16-0.21 0.09-0.14

TGMF 404 3.00 0.20 0.05 0.050 13.50 10.50 • • • • • • 0.25-1.80 0.18-0.24 0.09-0.15

TGMP 506 0.050 13.55 10.30 • • • • • • 0.50-1.80 0.21-0.32 0.11-0.20

TGMF 508 3.00 0.40 0.05 0.050 17.70 14.70 • • • • • • 0.20-2.40 0.23-0.35 0.11-0.21

TGMF 635-080 0.25-0.44 0.14-0.27

4.00 0.20 0.05 0.050 17.70 14.60 • • • • • • 0.50-2.40

4.00 0.40 0.05 • • 0.75-3.00

5.00 0.60 0.05 0.050 17.60 15.00

0.050 17.80 14.20 • • • • • • 1.00-3.00

5.00 0.80 0.05 0.050 22.15 18.60 • • • • • • 1.00-3.80

6.35 0.80 0.05

• DMIN for internal application=20.5 mm • For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: TGDR/L (270) • TGHN 26-M (354) • TGHN-D (271) • TGHN-S (271) • TGIR/L-C (353) • TGPAD (270) • TGPAD-JHP (271)

TGMF (full radius) INSL (Ref.)

Utility Double-Ended Full Radius

Inserts for External and Internal ±0.1

Grooving and Profiling

CW

RE

Dimensions Tough 1 Hard Recommended

Machining Data

IC830 ap f turn f groove

IC8250

Designation CW RE CWTOL(1) RETOL(2) INSL CDX(3) IC808 (mm) (mm/ (mm/

IC20 rev) rev)

TGMF 315 IC5010 0.18-0.26 0.07-0.13

TGMF 420 IC428 0.20-0.34 0.09-0.17

TGMF 525 0.23-0.42 0.11-0.21

TGMF 630 3.00 1.50 0.05 0.050 13.50 11.40 • • • • • 0.00-1.50 0.24-0.50 0.13-0.25

0.050 17.80 14.90 • • • • • • 0.00-2.00

4.00 2.00 0.05 0.050 17.75 14.30 • • • • • 0.00-2.50

0.050 22.15 18.30 • • • •

5.00 2.50 0.05 0.00-3.00

6.00 3.00 0.05

• Can cut arcs to 250° • DMIN for internal application=20.5 mm • For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: TGDR/L (270) • TGHN 26-M (354) • TGHN-D (271) • TGHN-S (271) • TGIR/L-C (353) • TGPAD (270) • TGPAD-JHP (271)

TGMA ±0.1 INSL

Utility Double-Ended Inserts for 15°

External and Internal Grooving

and Turning of Cast Iron CW

RE

Dimensions Recommended Machining Data

Designation CW RE CWTOL(1) RETOL(2) INSL CDX(3) IC5010 ap f turn f groove

TGMA 304K 3.00 0.40 0.05 0.050 13.50 10.30 • (mm) (mm/rev) (mm/rev)

TGMA 404K 4.00 0.40 0.05 0.050 18.00 14.60 • 0.50-1.80 0.12-0.20 0.07-0.13

TGMA 408K 4.00 0.80 0.05 0.050 18.00 14.50 • 0.50-2.40 0.16-0.27 0.09-0.18

TGMA 508K 5.00 0.80 0.05 0.050 18.00 15.00 • 1.00-2.40 0.18-0.32 0.09-0.19

TGMA 608K 6.00 0.80 0.05 0.050 22.40 18.60 • 1.00-3.00 0.23-0.40 0.11-0.24

1.00-3.60 0.27-0.48 0.14-0.29

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Cutting depth maximum

For tools, see pages: TGDR/L (270) • TGHN 26-M (354) • TGHN-D (271) • TGHN-S (271) • TGIR/L-C (353) • TGPAD (270)

272 ISCAR